All-in-one Fibre Splicing

Core network splicing - getting it right the first time

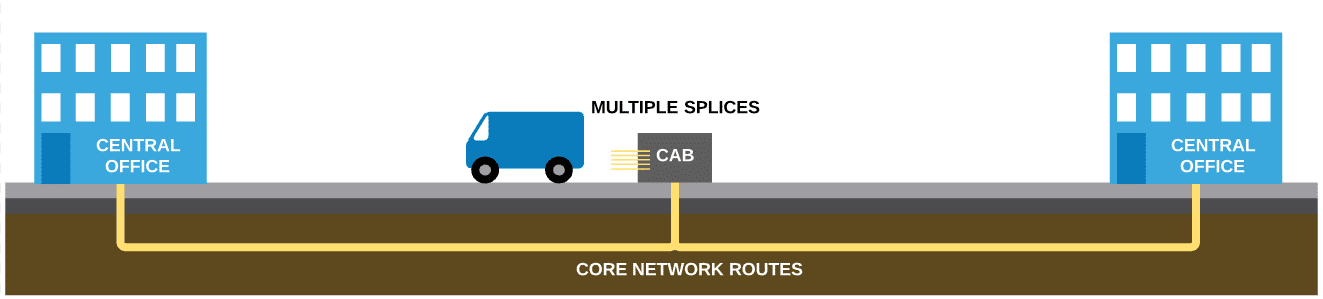

Fibre splicing on the core network requires high-quality, low-loss splices to be made, repeatedly, at every network location. As splicing is typically a manually performed process; however, a splicing technician can make errors while splicing.

Typical problems can include:

Not cleaning the fibre

Once the technician has stripped the fibre, it is essential to clean it to remove any remaining debris from the stripping process. Leaving any contaminants on the fibre will create additional loss in the splice.

Damaging the fibre

A common failure of spliced fibre is a fracture in the vicinity of the splice. The fracture may often be caused by the fibre being damaged during the stripping process. A splicing technician must use the correct tools for stripping to prevent the fibre being damaged. It may not be immediately apparent that the fibre is damaged as the fracture may only become evident once the fibre is subjected to some stress.

Unaligned fibre cores

It is possible to splice the two fibres in such a way that the core is not aligned correctly. Misalignment can especially be a problem if the cores are not entirely concentric. In cases where the fibres cores are not aligned when spliced, there will be increased loss in the splice.

Weak splice

If the fibre core is not completely clean or the electrode on the splicer is dirty or damaged then the splice may be weak and fail under stress.

Core network splicing involves splicing many fibres at specific locations on the network. It is essential that a repeatable process is followed.

Ensuring repeatability

Manual fibre splicing on the core network can result in splices suffering from any of these problems when the splice is completed. Working in an exposed environment can easily lead to contamination of the splice or poor alignment of the fibre. In many cases the poor splice may not be apparent until the fibre is replaced back within the duct, putting tension on the fibre cable.

All-in-one fibre splicers remove the variability from splicing, using automation to ensure that the splice is made in a repeatable manner and preventing the need for revisits to a location in order to perform remedial work.

5 step fibre splicing with automation built-in

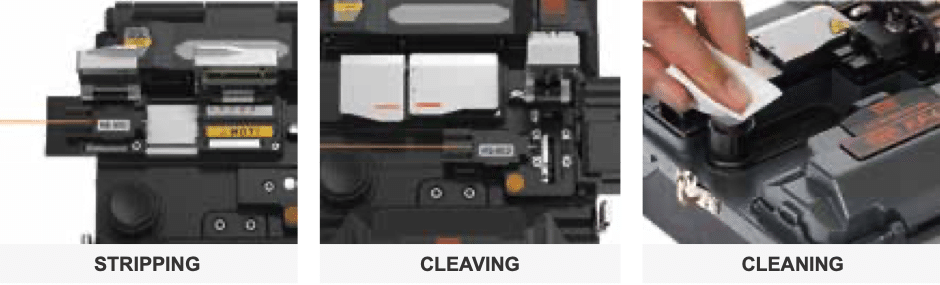

| Stripping | The K33A FTTH splicer futures an automatic stripper that removes the fibre coating and cladding, exposing the fibre core ready for splicing in just one second. |

| Cleaving | The single action cleaver makes a 90 degree cleave to the fibre end. The rotating cleaver blade can cleave up to 75,000 fibres before requiring replacement. Sharp ends are captured within the attached sharps container. |

| Cleaning | The built-in one-touch cleaning pump enables the technician to immediately clean the fibre end upon cleaving. |

| Splicing | The splicer automatically aligns the fibres and splices the fibre ends. The electrodes can support up to 38,000 splices before requiring replacement. Following the completion of the splice the quality is automatically tested through a tension test, ensuring the splice is good. |

| Protection | The splice is protected throughout the application of a heat-shrink splice protector. The built-in sleeving unit applies the splice protector within 30 seconds. |

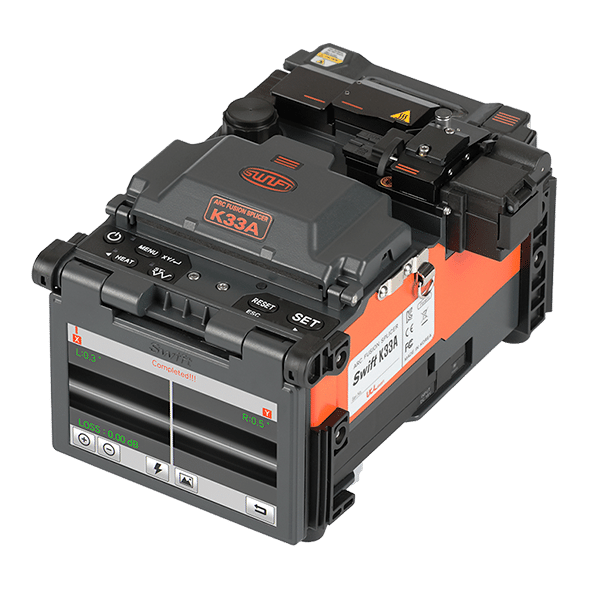

K33A - the key repeatable high-quality splicing

Supporting all the actions needed to make fibre splices using appropriate tooling, the automated splicing of the K33A delivers a repeatable high quality splice.

Built-in cleaning tools, cleaver, tensile strength test and automatic splice improve splicer teams productivity by removing the need for site revisits.

Request a demo today

See how the K33A can revolutionise how you deplloy fibre. Complete your name and email address below and we will contact you to arrange a demo.

All-In-One Core To Core Alignment Splicer

The K33A All-In-One Core To Core Alignment Splicer ensures high quality splices every time.

Combining five splicing functions into a single tool, the K33A ensures repeatable, low-loss splicing every time – improving your productivity.