FTTH Fibre Splicing

FTTH splicing - coping with distributed splice locations

FTTH deployment presents a brand new challenge for optical deployments: managing teams who now have to make only a small number of splices in any single location.

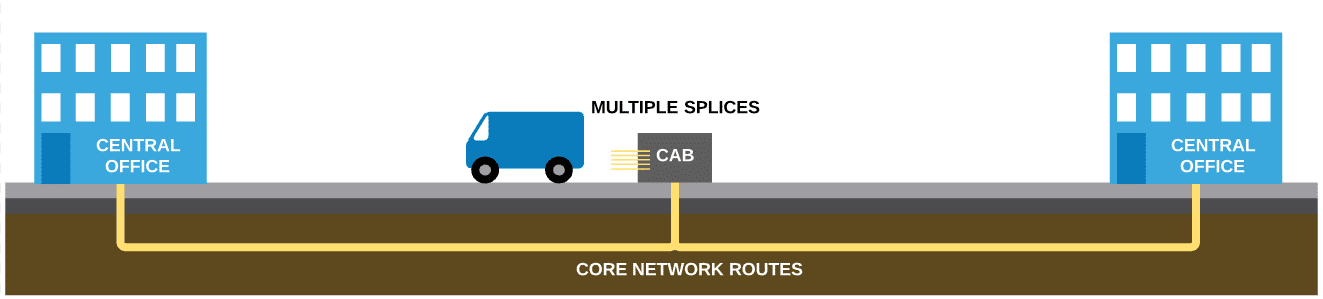

Traditionally fibre deployment was to support the installation of core networks or metro network. In these deployments, high-density fibre cables were deployed over a limited number of routes, requiring lots of splices being made at just a few locations.

As the core network expanded, splicing activities are planned in advance, with fibre splicing team deployments being managed to maximise efficiency.

Core network splicing involves splicing many fibres at specific locations in a managed plan

FTTH - connecting the consumer

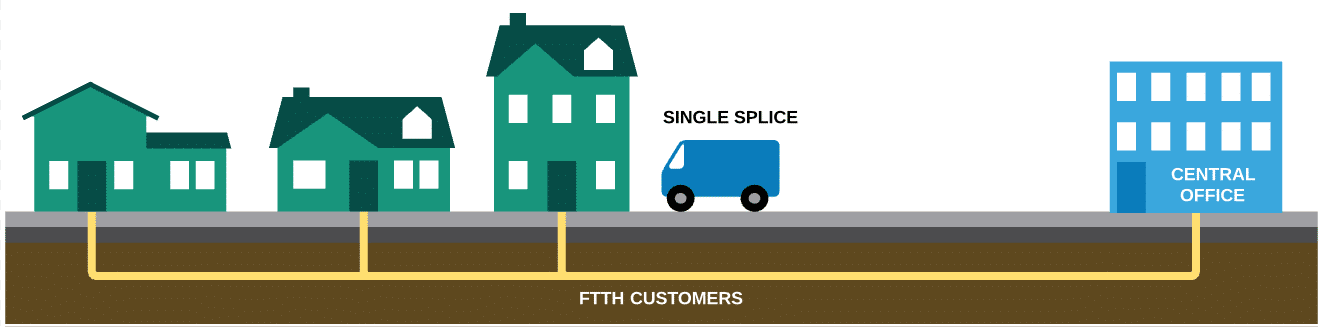

FTTH services can require splicing at every subscriber home in order to activate their connection to the network.

Typical connections use either a pre-terminated drop cable or the use of a splice-on connector to complete the link to the ONT.

In either instance, a splicing technician must visit the home of every new subscriber and splice on either the connector or the drop cable to connect the subscriber to their new optical Internet service.

Compared to ADSL (for example) this dramatically increases the on-boarding cost for a subscriber. For an ADSL subscriber, it is possible to ship an ADSL modem to the subscriber and expect them to make the necessary connections themselves. The cost of on-boarding the subscriber is limited to the cost of the modem plus associated shipping cost to the customer.

On-boarding an FTTH customer, however, requires a technician to visit every subscriber to connect their property to the optical network. These site visits dramatically increase the cost of on-boarding the subscriber and also reduces the number of subscribers the ISP can activate per day.

Reducing the time on site, and eliminating the need to revisit locations is essential to reduce the time taken to generate revenue, to achieve profitability, and to ensure customer satisfaction.

FTTH splicing requires a single splice to be made for each subscriber home

Splicing activity for FTTH activations are based purely on consumer demand – it is only necessary to perform any splicing once a consumer places an order for the FTTH service. In this way, the activity is purely reactive, and while some assumption of consumer demand can be made as the service is made available in new areas, it is not possible to plan in advance.

Consequently, a splicing technician needs to be able to have everything they need to be able to turn up at a subscriber, perform the splice and then leave as quickly as possible. This necessitates the following:

Minimising the amount of tooling required

Minimising the time taken on site

As the engineer may not be able to drive up and park next to the subscribers home, they may need to carry their tools from their vehicle location to the splicing location. To minimise the time on-site, they should only want to make a single trip from their vehicle to the home. So a combined splicing tool that performs every activity needed to activate the FTTH subscriber is the ideal solution to prevent having to make multiple trips to carry several tools.

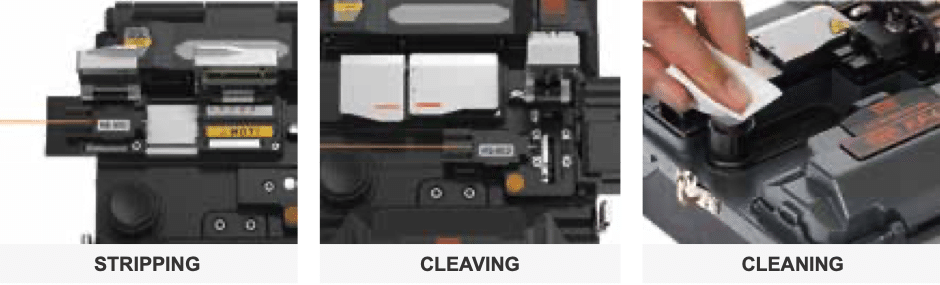

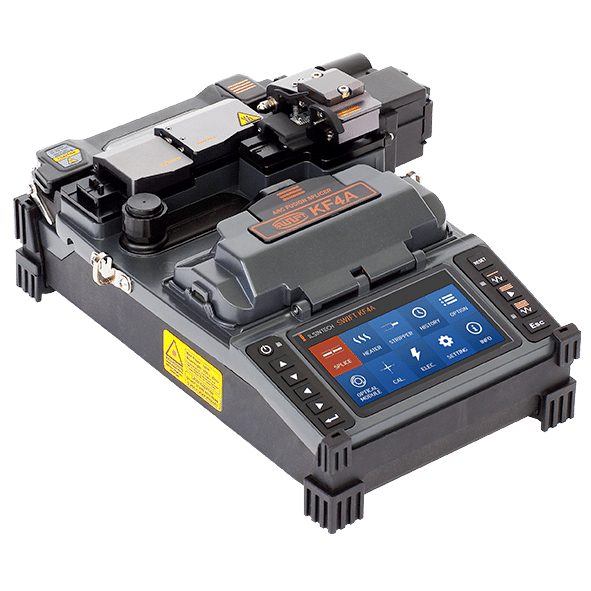

The KF4A All-In-One FTTH splicer combines the functionality of several tools into a single device, performing fibre stripping, cleaning, cleaving, splicing, protector application and testing into a single splicing device that is ideal for FTTH splicing and subscriber activation.

5 step FTTH splicing with automation built-in

| Stripping | The KF4A FTTH splicer futures an automatic stripper that removes the fibre coating and cladding, exposing the fibre core ready for splicing in just one second. |

| Cleaving | The single action cleaver makes a 90 degree cleave to the fibre end. The rotating cleaver blade can cleave up to 75,000 fibres before requiring replacement. Sharp ends are captured within the attached sharps container. |

| Cleaning | The built-in one-touch cleaning pump enables the technician to immediately clean the fibre end upon cleaving. |

| Splicing | The splicer automatically aligns the fibres and splices the fibre ends. The electrodes can support up to 38,000 splices before requiring replacement. Following the completion of the splice the quality is automatically tested through a tension test, ensuring the splice is good. |

| Protection | The splice is protected throughout the application of a heat-shrink splice protector. The built-in sleeving unit applies the splice protector within 30 seconds. |

KF4A - the key to FTTH subscriber activation

Supporting all the actions needed to make FTTH splices and bring consumers onto the network, the KF4A All-In-One FTTH Splicer enables a splicing technician to make a good splice first time, everytime.

Time on site is kept to a minimum through the easy-to-use automated functions of the splicer, and the automatic testing reduces the risk of a poor splice making a revisit necessary.

Subscriber activiation costs are kept to a minimum, reducing the time to achieve service profitability.

Request a demo today

See how the KF4A can revolutionise how you turn-up FTTH subscribers. Complete your name and email address below and we will contact you to arrange a demo.

All-In-One FTTH Splicer

The KF4A All-In-One FTTH splicer keeps the time to connect an FTTH subscriber to a minimum.

Combining five splicing functions into a single tool and using automation to ensure that a splicing technician makes a good splice every time, can connect a subscriber in a single visit, and makes the connection as expediently as possible, reducing the time-to-revenue.